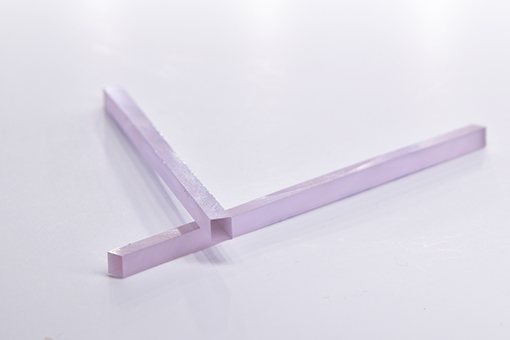

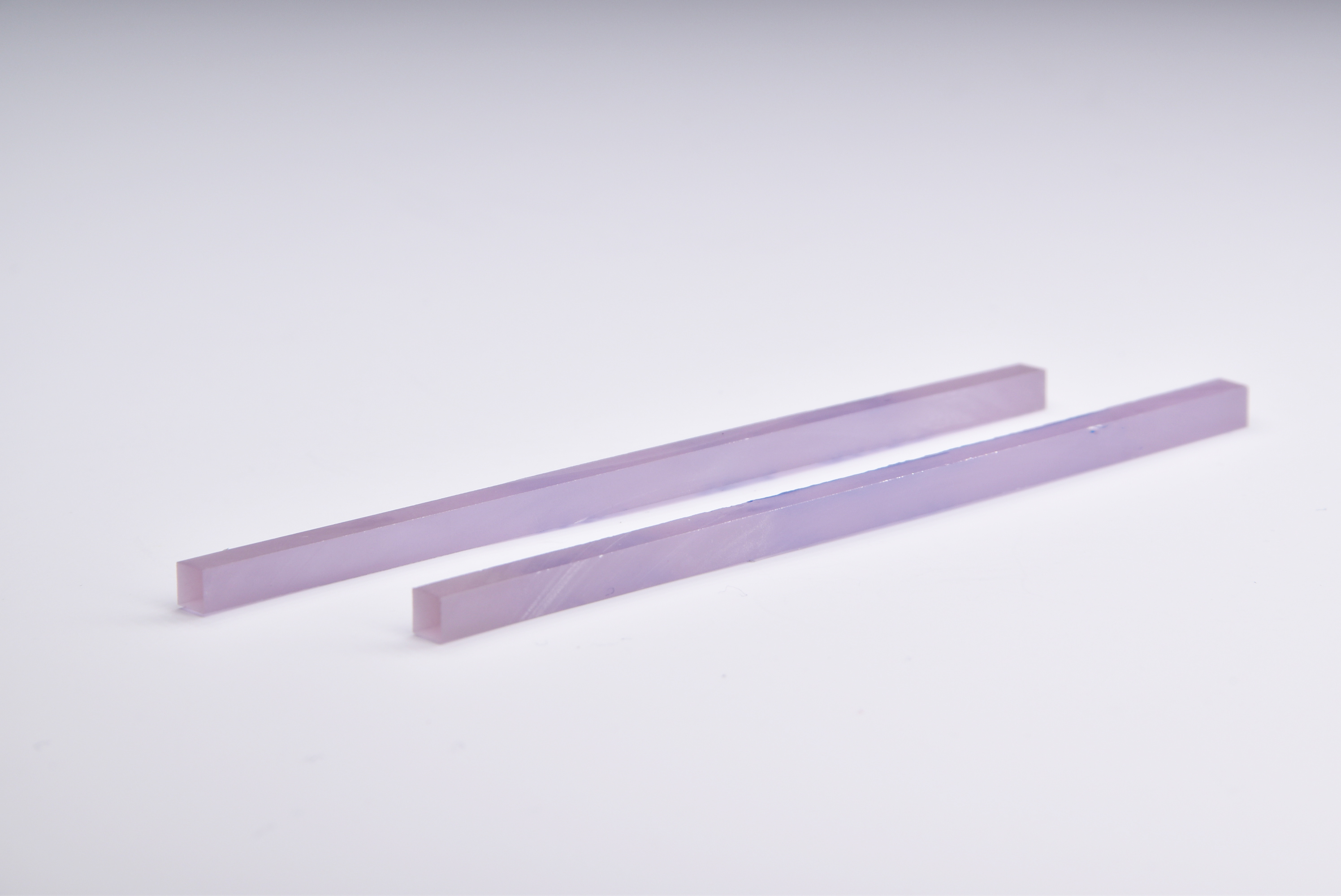

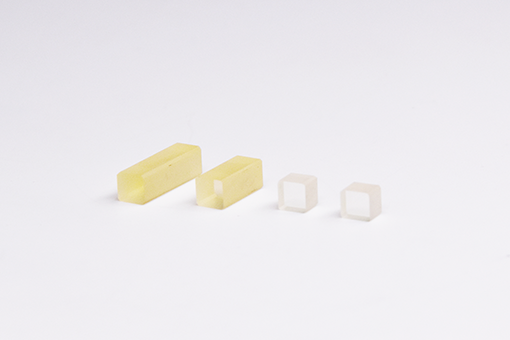

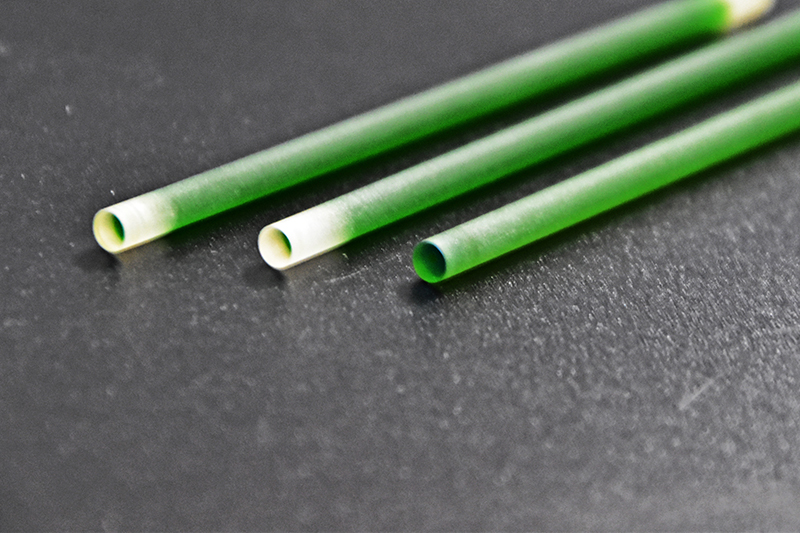

Nd:YAP Crystals

Nd:YAP AlO3 perovskite (YAP) is a well known host for solid state lasers. The crystal anisotropy of YAP offers numerous advantages.It permits a small tuning of wavelength by varyingthe wave vector direction in the crystal. Furthermore, the output beam is linearly polarised.

Advantages of Nd:YAP Crystals:

Comparable threshold and slope efficiency at 1079nm to Nd:YAG at 1064nm

Higher efficiency at 1340nm compared to Nd:YAG at 1319nm

Linearly polarized output beam

Higher absorption in water and body fluid of 1340nm compared to 1319nm

| Chemical Formula | YAlO3:Nd3+ |

| Crystal structure | D162h |

| Lattice Constant | a=5,176, b=5,307, c=7,355 |

| Refractive Index | na=1,929, nb=1,943, nc=1,952 |

| dn/dT | na:9,7×10-6 K-1 nc:14,5×10-6 K-1 |

| Density | 5,35 g/cm3 |

| Melting Point | 1870°C |

| Specific Heat | 400 J/(kg K) |

| Thermal Conductivity | 0,11 W/(cm K) |

| Thermal Expansion | 9,5 x 10-6 K-1 (a axis) 4,3 x 10-6 K-1 (b axis) 10,8 x 10-6 K-1 (c axis) |

| Knoop Hardness | 977 (a axis) |

Specifications:

| Dopant concentration | Nd 0.7-0.9 at% for cwand pulse t 1079nm 0.85~0.95 at% for cwat 1340nmOther dopant concentrations are available upon request. |

| Orientation | within 5° |

| Rod sizes | Diameter 2~10mn Length 20~150mm Upon request of customer |

| Dimensional tolerances | Diameter +0.00/-0.05mm, Length: ± 0.5mm |

| Barrel finish | Ground and polished |

| Parallelism | ≤10″ |

| Perpendicularity | ≤5′ |

| Flatness | < λ/10 @632.8nm |

| Surface Quality | 10-5(MIL-0-13830B) |

| Chamfer | 0.15±0.05mm |

| AR Coating Reflectivity | < 0.25% (@W64nm) |

Products categories

-

Phone

Phone

-

Email

Email

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Top